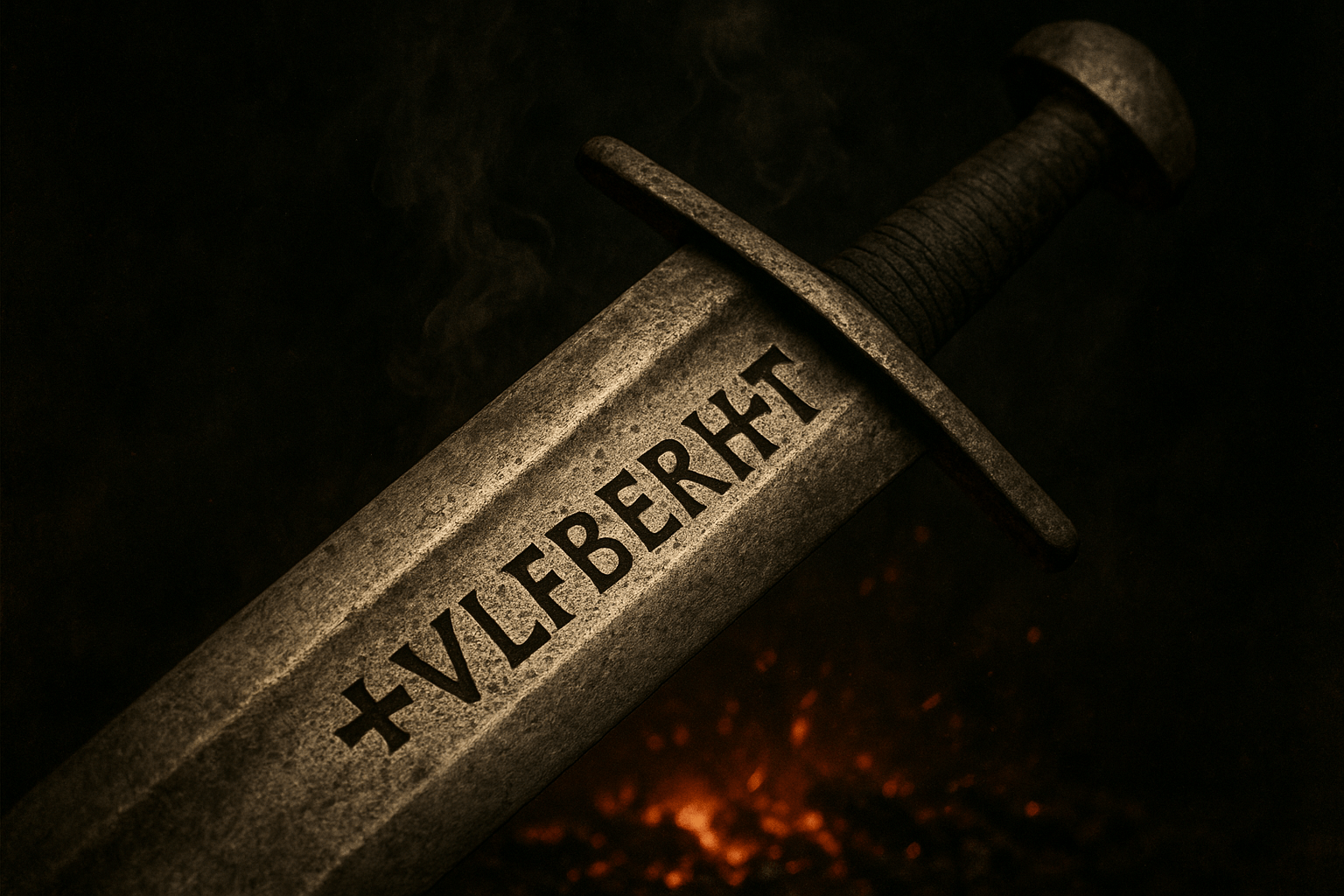

Picture a Viking warrior in the heat of battle. A shield wall splinters, axes clash, and amidst the chaos, a chieftain draws his sword. This isn’t just any piece of sharpened iron; it’s a status symbol, a weapon of legend, and a piece of technology so advanced it would baffle scientists a thousand years later. Inscribed on its blade is a single name: +VLFBERH+T. This was the mark of one of the most remarkable artifacts of the Viking Age—the Ulfberht sword.

A Cut Above the Rest

Between the 9th and 11th centuries, about 170 of these swords were forged. On the surface, they look like typical Viking-era blades. But when modern archaeometallurgists put them under the microscope, they discovered something astonishing. While most European swords of the period were made from relatively soft, impure “pattern-welded” steel—created by twisting and hammering together strips of iron and low-quality steel—the Ulfberht swords were different. They were forged from crucible steel.

This material was a game-changer. Here’s why:

- High Carbon Content: The Ulfberht blades contained up to three times more carbon than typical swords. This made them harder and allowed them to hold a much sharper edge.

- Extreme Purity: The process of making crucible steel removed most of the impurities, known as “slag.” Slag creates weak points in a blade, making it brittle. Without slag, an Ulfberht sword was incredibly strong and resilient.

- The Perfect Combination: The result was a blade that was both incredibly strong and flexible. It wouldn’t shatter on impact with a shield or another sword, nor would it bend and stay bent like softer iron blades. It was the “super-sword” of its day, capable of cutting through lesser mail and shattering weaker blades.

The steel was so pure, in fact, that European smiths would not be able to consistently replicate its quality until the Industrial Revolution, some 800 years later. This presented a profound mystery: how did Viking-era smiths create a material that was centuries ahead of its time?

The Mystery of the Vanishing Smith

“Ulfberht” is not the name of a Viking warrior, but a Frankish name, likely a trademark for a specific workshop or master smith operating in the Rhine region of modern-day Germany. These artisans were renowned for their skill, but even they did not possess the technology to create crucible steel from scratch. The furnaces required to reach the blistering temperatures of over 1600°C (3000°F) to liquefy iron and remove slag simply did not exist in Europe at the time.

So, if the European smiths didn’t make the steel, where did it come from? The answer rewrites our understanding of the Viking world, revealing it as a hub of a truly global network.

Forging a Path: The Volga Trade Route

The Vikings were more than just raiders; they were master navigators and tireless traders. Their longships, capable of crossing open oceans and navigating shallow rivers, allowed them to establish vast trade routes. One of the most important was the Volga Trade Route.

This riverine highway stretched from Scandinavia, down through the Baltic Sea, into the river systems of what is now Russia, all the way to the Caspian Sea. From there, it connected to the ancient Silk Road and the bustling markets of Persia and Central Asia. Archaeological evidence confirms this route was awash with goods: Arab silver coins (dirhams), silks, spices, and, most importantly for our story, high-quality steel.

For centuries, smiths in regions like modern-day Afghanistan, Iran, and India had mastered the art of making crucible steel, known to them as wootz steel (the material from which the legendary “Damascus” swords were made). They would seal iron ore and a carbon source (like wood or leaves) in a clay crucible, heat it for days in a special furnace, and allow it to cool slowly. The process produced a solid ingot of ultra-hard, pure steel.

The leading theory is that Viking traders bought these precious steel ingots in the markets of the Middle East and transported them thousands of miles back north. The genius of the Ulfberht swordsmiths was not in creating the steel, but in recognizing its superior quality and, crucially, knowing how to work with it. Forging this advanced material would have required incredible skill to avoid cracking it or ruining its temper.

The Brand and the Knock-Offs

The +VLFBERH+T inscription was more than a name; it was a brand, a guarantee of unparalleled quality. These swords were staggeringly expensive and would have been owned only by the wealthiest chieftains and most elite warriors. Owning one was a statement of power and prestige, the Viking equivalent of owning a supercar today.

The brand was so successful that it inevitably led to counterfeits. Archaeologists have found numerous swords from the period with the Ulfberht name—often misspelled, such as +VLFBERHT+ or with inverted letters—but made from common pattern-welded steel. These “fakes” tell a story of their own. They prove how legendary the genuine articles were; the name alone was so valuable that lesser smiths tried to cash in on its fame. Distinguishing a real Ulfberht from a forgery was, for a Viking warrior, a matter of life and death on the battlefield.

The Legacy of a “High-Tech” Blade

The Ulfberht sword is a powerful reminder that the past is more complex and interconnected than we often imagine. The so-called “Dark Ages” were pulsing with innovation and long-distance commerce that spanned continents.

This single artifact tells a story of global trade, advanced materials science, and expert craftsmanship. It’s a synthesis of Eastern metallurgical ingenuity and Western martial artistry, a perfectly forged link between the Viking raider of the cold North and the crucible steel master of the warm South. More than just a weapon, the Ulfberht is a testament to an ancient high-tech world, forever etched in steel.