What happened to the legendary Damascus steel? Was the recipe truly lost, or was it a victim of a changing world? To unravel this puzzle, we must journey back in time, not to the bustling markets of Damascus, but thousands of miles away to the heart of ancient India.

The Damascus Deception: A Tale of Two Steels

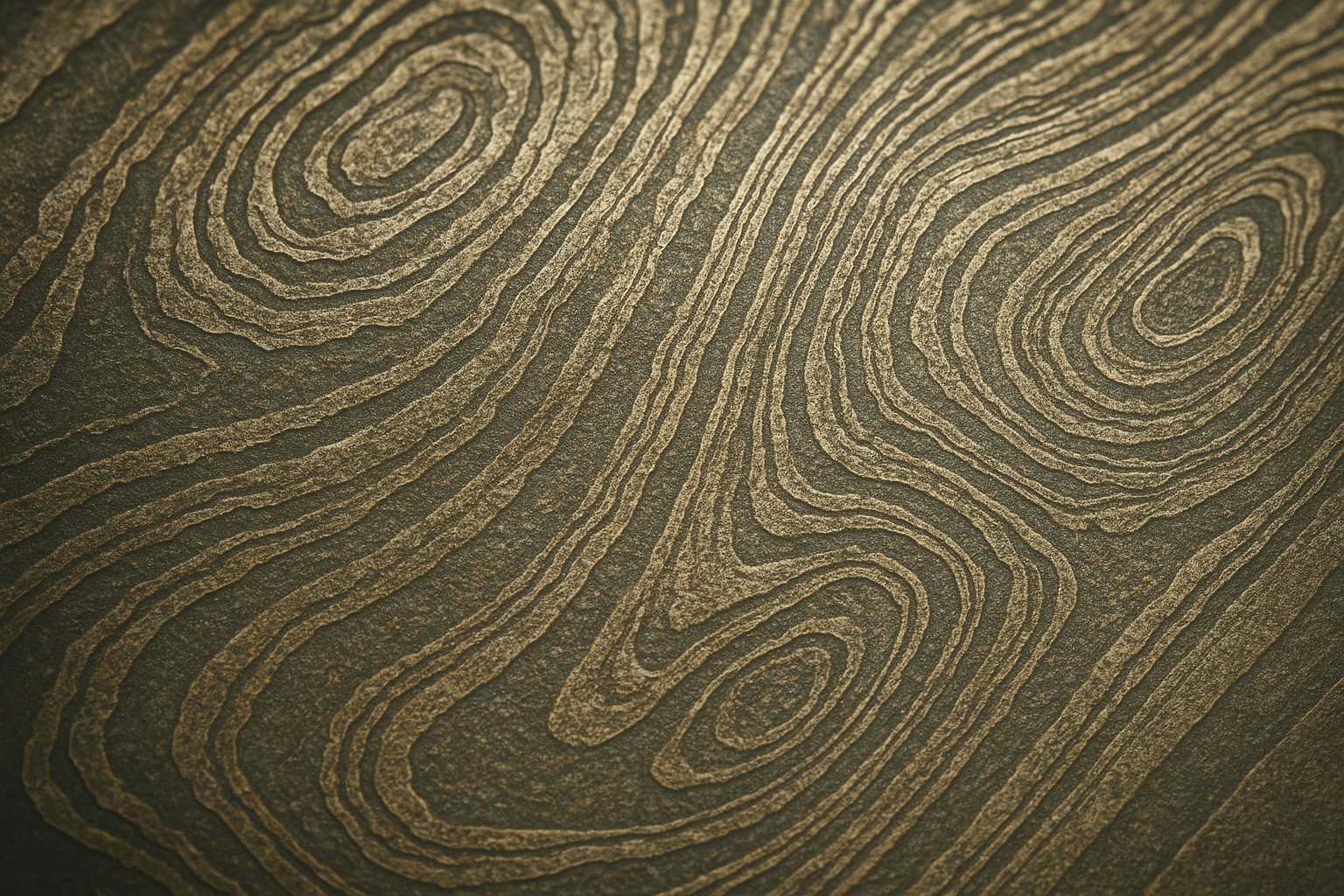

Before we delve into the mystery, it’s crucial to understand what we’re talking about. The term “Damascus steel” is often used today to describe modern blades with wavy patterns. This is typically pattern-welded steel, created by forge-welding multiple layers of different types of steel and iron together and then manipulating them to create a pattern. While beautiful and functional, this is not the material of legend.

Historical Damascus steel, the “true” version, was a type of crucible steel. The distinctive patterns were not created by layering; they were inherent to the molecular structure of a single piece of steel. The blades were forged in cities like Damascus, a major center for the arms trade, which is how the steel got its name. But the raw material itself, the secret ingredient, was a specially prepared steel ingot known as “wootz.”

The Indian Connection: Wootz, The Miracle Ingot

The story of Damascus steel begins in ancient India and Sri Lanka, where metallurgists had perfected a remarkable technique for creating ultra-high-carbon steel around 300 BCE. This was wootz steel.

The process was a marvel of early engineering:

- Black iron ore (magnetite), along with glass and specific types of carbon-rich materials like bamboo or leaves, were sealed inside a small clay pot, or crucible.

- These crucibles were placed in a high-temperature furnace and heated for an extended period. The carbon would be absorbed by the molten iron, creating a steel with a very high carbon content (around 1.5% to 2.0%).

- The crucial step was the cooling. The crucibles were cooled very slowly over several days. This slow cooling allowed the carbon within the steel to precipitate out and form microscopic clusters of iron carbide (Fe₃C), also known as cementite.

The result was a solid puck or ingot of wootz steel. To the untrained eye, it looked unremarkable. But within its crystalline structure lay the seeds of the legendary patterns and properties of a Damascus blade. These ingots were traded along ancient routes, making their way to the master smiths of Persia and the Near East.

The Art of the Damascene Smith

If the Indian metallurgists were the producers of the raw ingredient, the smiths of Damascus were the master chefs. They possessed the esoteric knowledge required to transform a wootz ingot into a legendary weapon. Forging wootz was incredibly difficult; heated too much, and the delicate carbide structures would dissolve, ruining the pattern. Not heated enough, and the high-carbon steel would be brittle and crack under the hammer.

The Damascene smiths worked the steel within a narrow temperature window, carefully hammering and shaping the blade. This meticulous process, known as thermal cycling, didn’t create the patterns but rather aligned the existing bands of cementite particles. Once the blade was forged, it was polished and etched with a mild acid. The acid would eat away at the softer steel matrix faster than the hard cementite particles, revealing the stunning, water-like pattern—known as the damask—that made the blades famous.

This network of hard carbide bands suspended in a softer, more flexible steel matrix gave the blades their dual properties: an incredibly hard, durable cutting edge that stayed sharp, combined with an overall toughness and flexibility that prevented the blade from shattering upon impact.

The Lost Recipe: A Perfect Storm of Disappearance

So, why did the production of wootz Damascus steel cease around the mid-18th century? The “lost recipe” theory is compelling, but the truth is more complex. Production ended due to a confluence of factors that broke the chain of knowledge and supply.

- Disruption of Supply Chains: The primary source of wootz steel in India, particularly in the Golconda region, began to decline. Whether through political instability, warfare, or the exhaustion of key resources, the flow of high-quality wootz ingots to the Middle East dwindled and eventually stopped.

- Loss of Trace Elements: Modern analysis suggests that the specific Indian ore used to make wootz contained minute impurities—trace amounts of elements like Vanadium and Molybdenum. These elements acted as “carbide-formers”, encouraging the formation of the cementite bands during the crucible process. It’s possible that the original mines ran out of ore with this specific, unique chemical makeup. Without these crucial trace elements, new batches of steel wouldn’t perform the same way.

- Erosion of Craft Knowledge: Damascus forging techniques were trade secrets, passed down orally from master to apprentice over generations. When the supply of wootz dried up, there was no longer a need for this specialized skill. Within a few generations, the unwritten knowledge of how to properly heat, hammer, and work the unique steel was lost to time.

The Modern Quest to Resurrect a Legend

The mystery of Damascus steel fascinated scientists for centuries. In the 19th century, the famed English scientist Michael Faraday studied wootz ingots, but failed to uncover their secrets. The puzzle remained unsolved until the 20th century, when modern metallurgical science provided the tools to look deeper.

In the 1980s, a breakthrough came from an unlikely partnership between a bladesmith, Alfred H. Pendray, and a metallurgist, Dr. John D. Verhoeven. By analyzing historical blades and meticulously experimenting with crucible steel formulations based on old accounts, they successfully created blades that exhibited the chemical composition and microstructure of classic wootz steel. They rediscovered the critical role of trace impurities and the precise temperature controls needed for both the crucible and forging processes.

More recently, in 2006, researchers at Dresden University in Germany used advanced electron microscopes to examine an authentic 17th-century Damascus saber. They made a startling discovery: the steel contained carbon nanotubes and cementite nanowires. This ultra-modern nanostructure, created unwittingly by the ancient smiths, is believed to be responsible for the steel’s incredible strength and resilience.

A Mystery Solved?

Today, we understand the science behind Damascus steel. We know it was a high-carbon crucible steel called wootz, whose unique properties came from a specific chemical makeup and a masterful forging process. We have even replicated it in modern labs and workshops.

Yet, the legend endures. The true “mystery” was never just a single lost recipe. It was the loss of an entire ecosystem—of unique mineral deposits, unbroken trade routes, and centuries of artisanal knowledge passed through generations. We may have reverse-engineered the steel, but we can only stand in awe of the ancient craftsmen who, through trial, error, and immense skill, perfected a material so advanced that it baffled science for over 200 years.